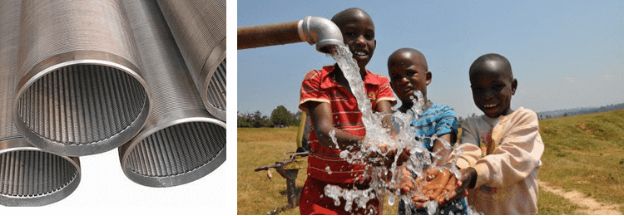

Since the earliest of human civilization, water has played an important role in its development. From agricultural purposes, to conquering new lands, to survival, water sources such as water well Screens are essential to the success of the project or purpose and as such, the construction of the water well are scrutinized to ensure that clean water is filtered and the borehole is protected from contaminants.

Due to the varying designs and constructions offered throughout the world, it may be difficult for many who are interested in water well construction to decide on the designs they want. That said, whatever design one chose, the efficiency of the well as well as its durability still depends on the casing and the water well screen that completes the well construction.

Water Well Casings

Casings maybe installed using the cable tool method where the casing is installed while drilling is taking place. When this method is used, a water well screen is created on the opposite side of the water area. This method is often used for places that have harden formations or where surface area is coarser than norm. Although cable tool method is effective, many now prefers using the direct rotary method. This method is preferred since control loading is available unlike with the cable method.

Casings and Screens

Due to the pressure that comes with water wells, it is important that the casing and water well screens are made with durable materials that can withstand different stressors. The resistance of the screens and casings must be more than the required external forces in order to be effective. External forces includes caving, sloughing and any forces that will cause the pipes to rupture.

One of the popular water well filter screen are those made with steel. Although steel is easily the best material to use as it is resilient especially for deep wells, other casings and screen materials that are equally acceptable are plastics for shorter or shallow wells and concrete material.

Well Screen Specification

It is important that wedge wire filter screens developed would perfectly fit the casing. As sizes differs, there are no specific dimensions required. That said, one can order their required casing, dimensions are measured according to the customer’s needs and specifications. It should be remembered that the aperture size must properly be retained and must be consistent with size of the aperture to prevent and retain the filter pack. Proper screens minimizes the pressures when water comes in to the well and may also be used to. To developed water wells, design specification are check first to ensure smooth installation or maintenance of the area.

Types of Screen Design

Water Well Screens comes in different sizes and shape, one of which is the torch cut slots. Torch cuts are not favorable and is only included because of its vertical slots. Another design is the milled slots which are commonly used in the agricultural sector. The slots are ideal for the oil sector as it can segregate the slow production that happens in the oil sector.